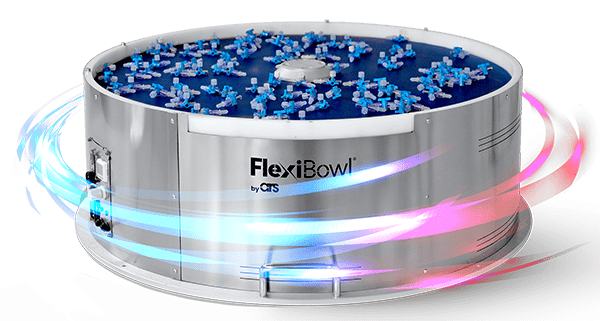

WHY CHOOSE FLEXIBOWL®?

FlexiBowl® orients and separates parts and can be integrated with any vision system and any robot for parts feeding.

The FlexiBowl® system is highly versatile, capable of feeding parts between 1 and 300 mm and from 1 to 300g, regardless of:

- Geometry

- Surface

- Material

Its lack of production-specific tooling and its easy-to-use and intuitive programming permit quick and multiple product changeovers even during the same work shift.

FlexiBowl® is available in 6 models.

Choosing the right model

Make the right choice according to:

- Expected productivity;

- Required orientation of the components that are going to be fed;

- How parts should be set down;

- Overall dimensions and available space;

- Interactions with other features on the production line;

- Reference standards and regulations;

- Characteristics of the production setting

Analysis and free test

The best solution is the one that meets the requirements of the production line. For years, our project office has helped distributors, machine manufacturers and integrators all over the world select the right FlexiBowl®.

We provide a free test so you can see how the system works with the parts it actually has to handle, and we help you identify the right model and optional accessories. The free test is practical guidance to help you make the right choice for the most competitive solution.

FLEXIBOWL® 200

Ideal for 1-10mm components

VIDEOS

6 x 4 mm

10 x 5 mm

30 x 70 mm

FLEXIBOWL® 350

Ideal for 1-20mm components

VIDEOS

6 x 4 mm

10 x 1 mm

2 x 2 mm

20 x 1 mm

FLEXIBOWL® 500

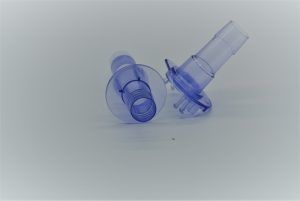

Ideal for 5-50mm components

VIDEOS

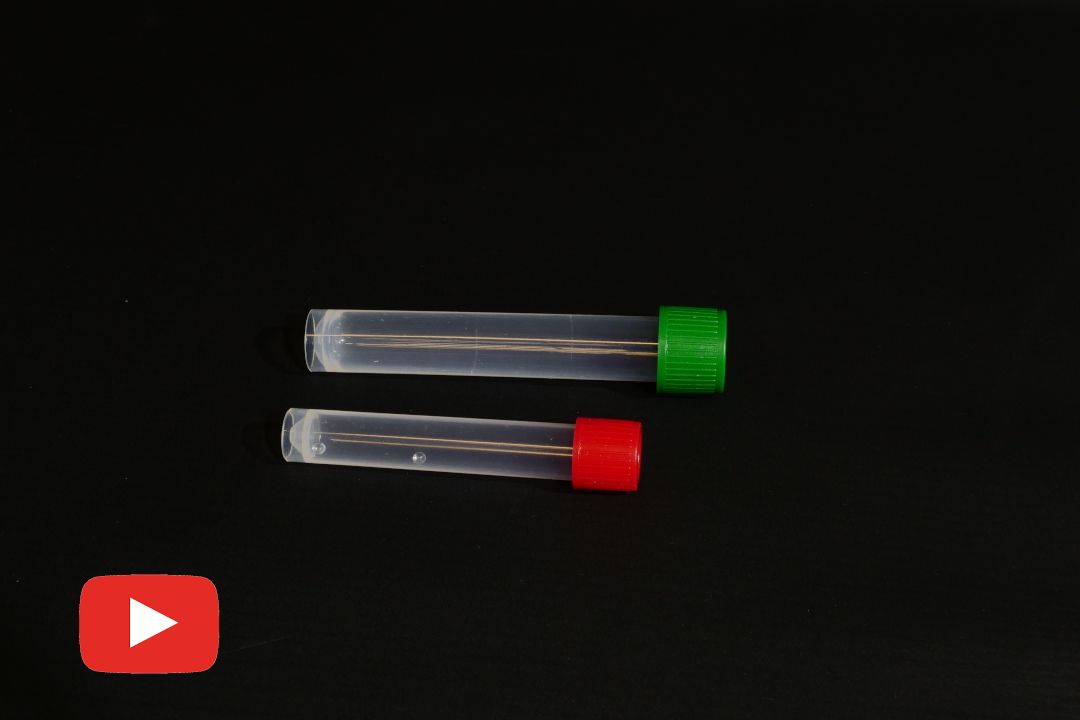

30 x 10 mm

40 x 20 mm

55 x 19 mm

50 x 10 mm

FLEXIBOWL® 500 E

Ideal for 5-50mm components

VIDEOS

30 x 10 mm

40 x 20 mm

55 x 19 mm

50 x 10 mm

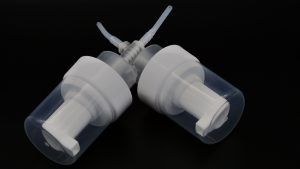

FLEXIBOWL® 650

Ideal for 20-110mm components

VIDEOS

103 x 21 mm

147 x 5 mm

160 x 20 mm

100 x 3 mm

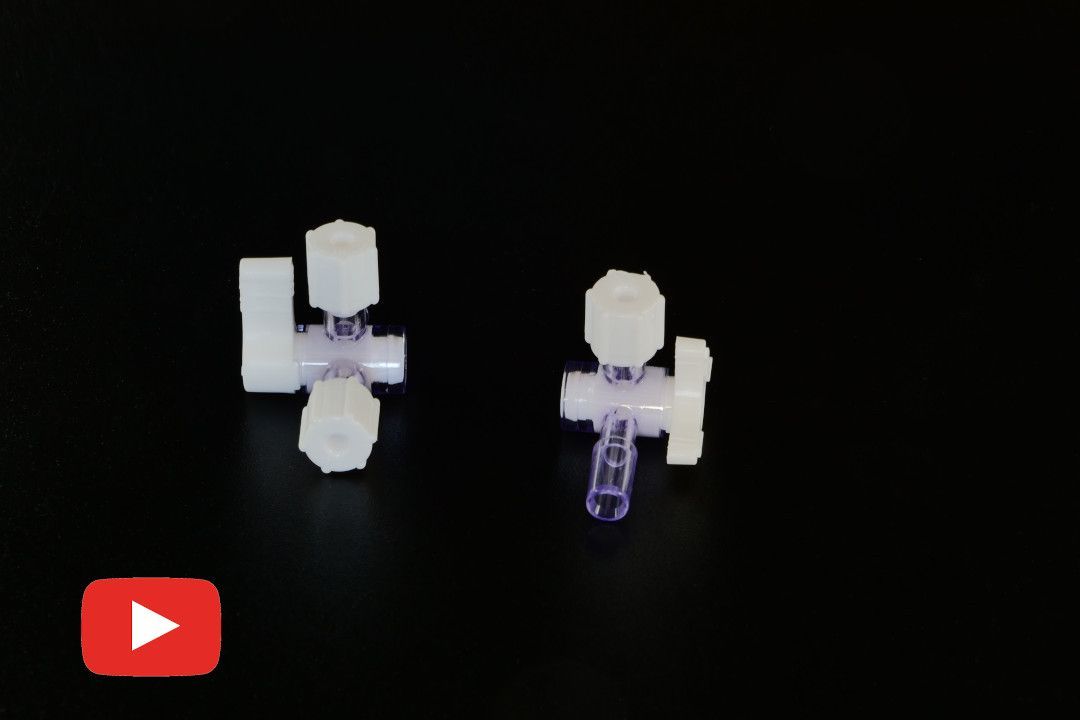

FLEXIBOWL® 800

Ideal for 60-250mm components

VIDEOS

85 x 5 mm

250 x 25 mm

215 x 5 mm

100 x 17 mm

FLEXIBOWL® 1200

Ideal for 50-300mm components

VIDEOS

85 x 5 mm

250 x 25 mm

215 x 5 mm

100 x 17 mm

Operating Modes

Traditional, FlexiTrack or Multiple Parts Feeding.

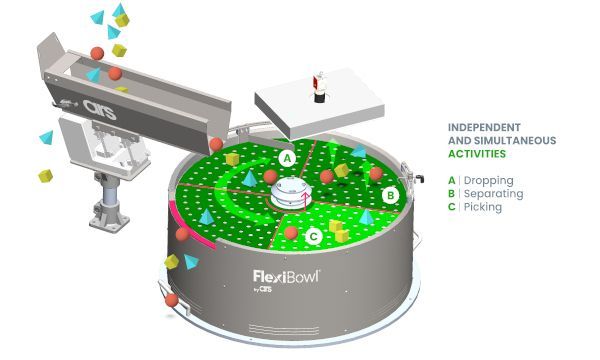

Traditional

FlexiBowl® is the only system that has a circular sequence consisting of feeding, rotation, jogging and pick-up. These actions are performed in parallel to prevent stalling, but also to achieve fantastic benefits in terms of efficiency. Perfect for extreme picking precision.

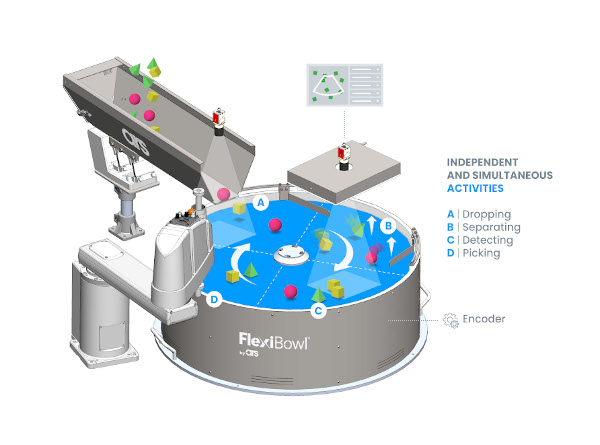

FlexiTrack

The motor and the flip mechanism work continuously to rotate the disc constantly and smoothly. Greater productivity is achieved with a touch less precision. Perfect for parts with simple geometries.

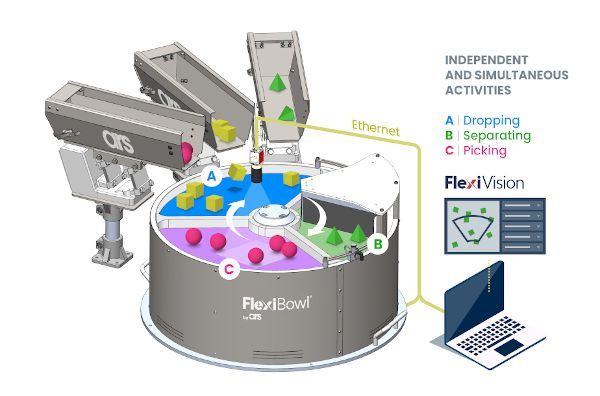

Multiple Parts Feeding

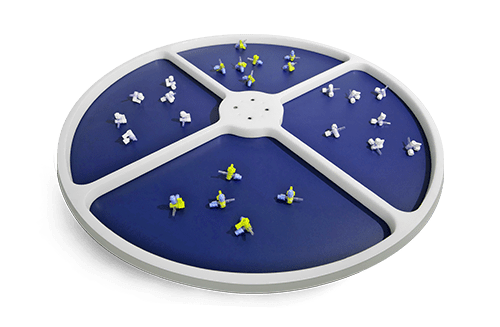

Handles up to 4 types of parts simultaneously. Minimizes layout and production costs in processes that use several parts simultaneously.

ADVANTAGES

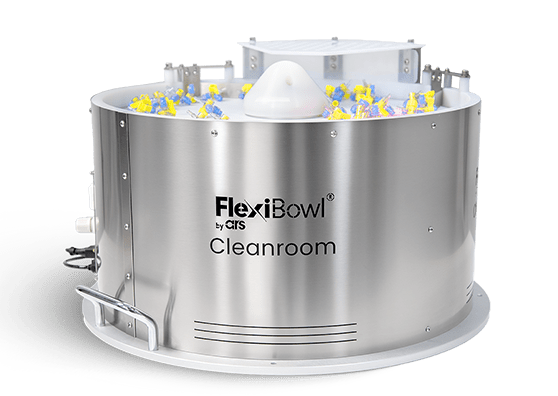

Cleanroom

This option is certified for use in ISO 5 Cleanrooms according to ISO 14644-1, while retaining all the FlexiBowl® features.

Flexibility

Pulse speed, acceleration and frequency are easy to modify. Optimal separation can be achieved for each part enabling frequent production changeovers. Electronic and mechanical systems work together programming and reprogramming of the software.

Speed

Higher speed rate means better productivity. FlexiBowl® is often the choice when it comes to fulfilling significantly large orders, because of the extraordinary quantity of parts it processes.

Easy to use

No special technical training needed for programming. Operators can handle the system autonomously right from the first use. FlexiBowl® is perfect for frequent production changeovers taking just a few seconds, with no need for long mechanical retooling.

Easy to reprogram

FlexiBowl® can be reprogrammed and made even more powerful with further options for any transformation the production line has to undergo to meet market needs. The parameters of FlexiBowl® are extremely easy to modify.

Compatibility

FlexiBowl® is compatible with all cobots and industrial robots that support the Ethernet (TCP/IP, UDP/IP), Ethernet/IP, digital I/O protocols. Plug-ins are available for communication with robots.

Integration

FlexiBowl® can be deployed on production lines in numerous industries. Its range of options is designed to offer customization and perfect integration: dispersion and deflection systems, cleanroom version, FDA-compliant and anti-static surfaces, and much more besides.

Reduced wastage

FlexiBowl® allows parts to be fed without damaging them: the quality of the action exceeds that of traditional solutions. Parts are handled with greater precision and care. No parts wasted and increased productivity.

Self-reliant but never alone

We provide support at all stages: from the choice of system, to shipping, set up, start up and during operation and changeovers. Routine maintenance is drastically reduced compared to traditional technologies. Our goal is for you to feel self-reliant but never alone.

OPTIONS

We can help you choose the best options for your components

Backlight

Available in IR, red or white

Toplight

Available in IR, red or white

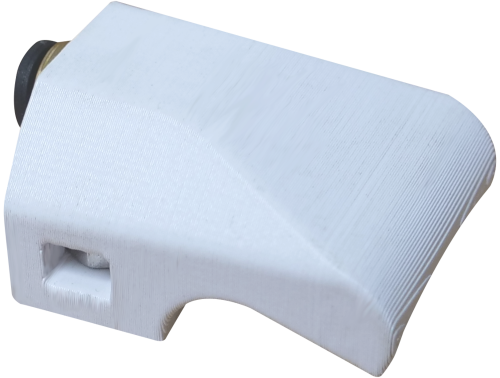

Air-Blow

Moves the tiniest components away from the edge

Standard diverter

Redirects the components from the edge

Brush diverter

Redirects the components from the edge

Wedge diverter

Components deviation system consisting of a wedge located between the steel surface and the rotary disc

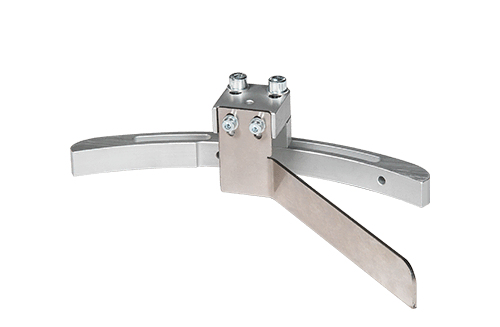

Quick emptying

For fast product changeovers (FlexiBowl® 500, 650 & 800)

Custom grooved disc

Design upon request

Multiple parts feeding

Simultaneous feeding of different components

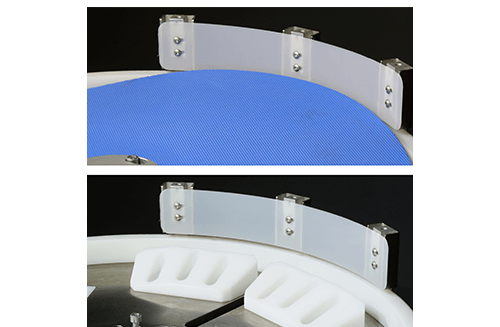

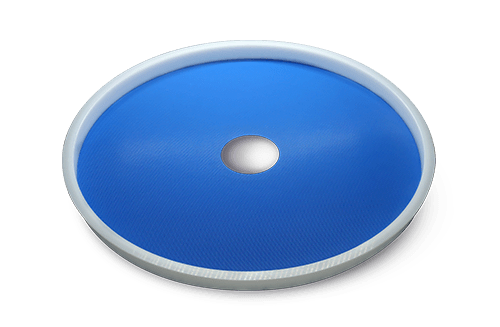

Round edged disc

The Rotary Disc is available in various colours, textures, degrees of surface adhesion for FlexiBowl® 200, 350 & 500E

Rotary disc

The Rotary Disc is available in various colours, textures, degrees of surface adhesion for FlexiBowl® 500, 650 & 800

Cleanroom version

Pre-installed bundle for compatibility with Cleanroom class ISO 5. Available for FlexiBowl® 500, 650, and 800

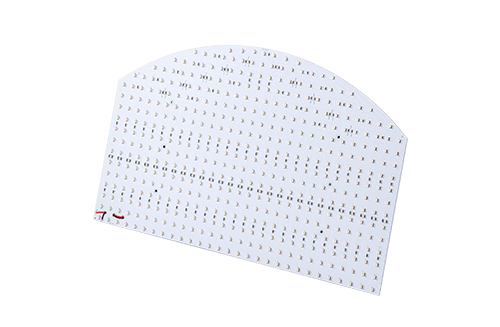

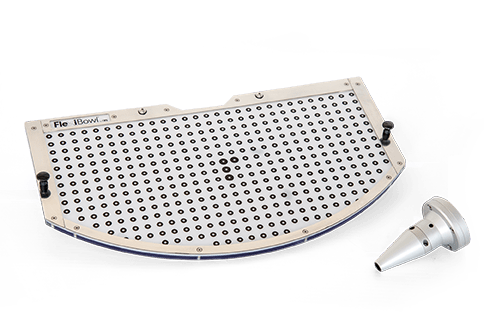

Calibration Plate

Specific calibration plate tailored on the FlexiBowl® vision area, allows you to reach the maximum accuracy and repeatability

FlexiTrack

Enables the circular conveyor tracking of the FlexiBowl®

Remote Control Box

Separate electrical cabinet to remote the internal electronic parts of the FlexiBowl®

FlexiBowl® IP40

Pre-installed kit to increase FlexiBowl® degree of protection up to IP 40